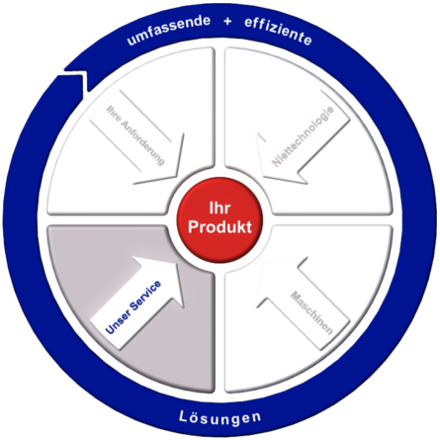

Riveting process

The rivet - a riveting word indeed!

In any context involving use of the word 'rivet', one thing always emerges clearly and strongly: A rivet connection is one of the safest, fastest and most cost-effective processes for the permanent, positive or also non-positive connection of components made of identical or even of very different materials.

The quality of a rivet connection or of a lug or tubular rivet connection depends to a large extent on the technology applied. The type of riveting technique used depends on a vast array of diverse requirements. The requirements on a rivet connection are also determined by the choice of the correct connecting element.

For example, for the selection of a riveting process and connecting element, the following questions typically get asked:

- Is the component being riveted a safety component, e.g. an element in an airbag system,

- the light alloy brake disc in a motor vehicle of a safety belt for a collision protection system etc.?

- Does the rivet or lug perform a decorative function?

- Is a rotating rivet or lug connection wished for?

- Is a positive connection required with friction connection required?

- Can friction connection forces destroy the components being riveted,

- or damage them to such an extent that their function is no longer assured?

- usw.

The requirements determine the processing technology to be applied:

- compressive riveting process

- tumble rivet process

- radial riveting process

- stamp riveting process

- blind riveting technique

Rivet connections should therefore be co-determined by the specialist.